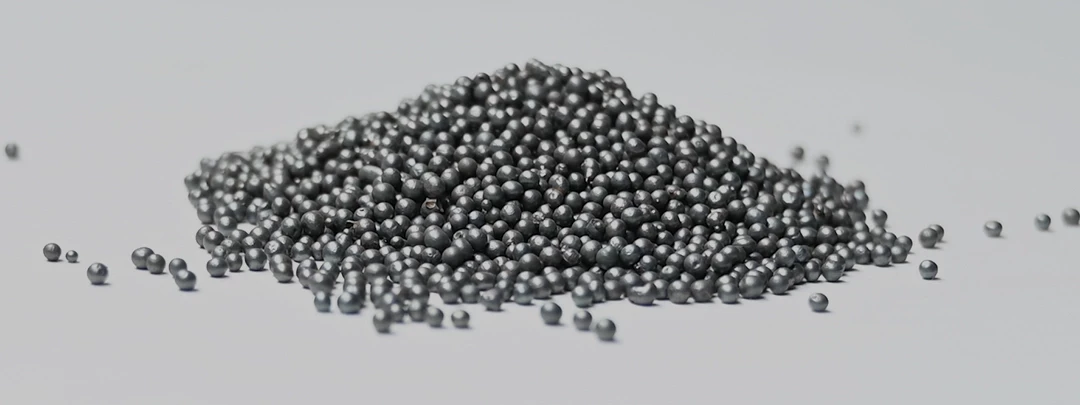

Abrasive Steel Shot Manufacturers in Pune| Abrasive Steel Shots in Pune

White Gloss Engineering is well-known Abrasive Steel Shot manufacturers, suppliers, dealers, distributors, traders in Pune. Our Abrasive Steel Shot solution products are developed to achieve the utmost level of efficiency and quality to deliver a dependable performance to a broad range of uses. Be it cleaning of surfaces, rust and scale removal, stripping of paints and coats, or shot peening to increase the strength of the material, our steel shot gives the same and accurate results each time.

Steel shot is commonly employed in the shot blasting, shot peening and in industrial cleaning practice in the automotive, manufacturing, and construction sectors.

What is Steel Shot?

Steel Shot is composed of little, spherical steel balls that are used to clean, finish and prepare surfaces. It is rounded in shape so that uniform impact can be achieved without damaging the base material to remove rust, scale, paint, or any other contaminants.

Types of Steel Shot

We are best steel shot manufacturers in Pune and we provide following types of steel shots in industry.

-

Low Carbon Steel Shot

Relatively soft and less aggressive Low carbon steel shot is used in applications such as shot peeling where surface compression is used to increase the fatigue life of metal components without compromising the surface. -

High Carbon Steel Shot

High carbon steel shot is tough and hard hence can be used in blasting processes that are aggressive. It is very effective in removal of rust, scale and other tenacious contaminants so as to leave the metal surfaces clean and ready for further processing. -

Stainless Steel Shot

Stainless steel shot is very resistant to corrosion, and gives a bright rust free finish. Steel shot suppliers in Pune generally applicable in industries that value hygiene and appearance like food processing, medical equipment and automotive components. -

Cut Wire Shot

Cut wire shot is created by cutting steel wire to balls of equal size. It has a uniform size and strength which makes it very suitable in cleaning, deburring and finishing of surfaces accurately depending on its composition. -

Cast Steel Shot

Cast steel shot is produced by pouring the molten steel into the mould creating uniform and hard pellets. It is also a multi-purpose tool suitable in both shot blasting and shot peening and has long service life. -

Chilled Iron Shot

Heat treatment of cast iron makes chilled iron shot very hard and wearing. It is best applied in the case of heavy-duty abrasive cleaning to use like old coating or thick rust or stubborn deposits present in industries.

Technical Specifications of Abrasive Steel Shot

Serve as top steel shot suppliers in Pune here are the technical specifications of steel shots.

| Specification | Details |

|---|---|

| Shape | Spherical and solid |

| Hardness | 40–50 HRC (Rockwell C) or 400–540 HV (Vickers) |

| Size | Varies by grade (S-70, S-280, S-330, S-930); 0.18 mm to 2.80 mm or larger |

| Density | ≥ 7 g/cm³ (487 lb/ft³) |

| Chemical Composition | Iron and carbon (0.85–1.20%); small amounts of manganese, silicon, phosphorus, sulphur |

Features of Abrasive Steel Shot

We are distinguished steel shot dealers in Pune and below are the important features of our products.

-

Spherical Shape

The rounded shape enables the steel shot to leave a smooth and polished finish on the surface at all places. -

Great Durability and Strength

Steel shot manufacturers in Pune provide steel shots that are able to withstand high impact force and be recycled making it durable and dependable. -

Magnetic

Certain steel shots are also magnetic and this can assist in effortless amassing and recycling when cleaning. -

Multiple Hardness Options

Steel shot services in Pune come in various grades and can be selected depending on the cleaning/ finishing process. -

Low Dust Production

It generates less dust in the blasting process making the working environment cleaner and safer.

Benefits of Abrasive Steel Shot

Here are the key advantages of our products as steel shot distributors in Pune

-

Cost-Effective

It is long-lasting, reusable, and do not require high frequency of replacement, and this makes it an economical long-term option. -

Efficient Cleaning

It works in less time and consumes less material thus completing the project in less time with less wastage. -

Enhanced Surface Finish

Steel shot manufacturers in Pune provides an even, bright and smooth surface and better adhesion to apply coating and a professional appearance. -

Improves Material Strength

In shot peening, steel shot creates compressive stress and makes metals more fatigue resistant and longer lasting. -

Environmentally Safe

Steel shot is non-hazardous and has a smaller environmental impact compared to other more damaging abrasives.

Applications of Abrasive Steel Shot

We are notable steel shot traders in Pune and our products are widely applicable in following.

-

Surface Preparation

Metal surfaces are prepared with steel shot and then painted and coated or bonded. This process of roughening the surface a bit helps to improve adhesion and long life finishes. -

Cleaning and De-Scaling

It is useful in removing the rust, scale, oxides and residues of castings, forgings, and machined parts leaving the surface clean and prepared to continue processing. -

Shot Peening

Steel shot is applied in the strengthening of metal parts in automotive, aerospace and heavy engineering. The process enhances components fatigue resistance and prolongs the life of the components. -

Paint and Coating Removal

Steel shot service providers in Pune are perfect in restoration projects as well as maintenance projects to strip off old paint, powder coating, and other coatings off metal, wood, or concrete. -

General Metal Finishing

Steel shot is used to give a polished and smooth finish to components made of metal, both to make them look better and to improve the functionality of the component used in machinery, tools, and decorative accessories.

Why Choose Us?

- Quality Materials - We have high-quality steel shot that guarantees uniform outcomes and high-quality performance.

- Efficient and Reliable Service - Fast, accurate and safe solutions to all your surface cleaning and finishing requirements.

- Professional Advice- Our team will assist you to select the appropriate type of shot and process to use in your unique industrial project.

White Gloss Engineering is recognized Abrasive Steel Shot manufacturers, suppliers, dealers, distributors, traders in Pune. Our Abrasive Steel Shot solutions make sure that your surfaces not only appear clean and polished, but also in the harsh world of industry, they perform better. With its durability, efficiency and high-quality performance, our steel shot can aid in increasing the lifespan and reliability of your components and ensuring low operational costs. Our steel shot makes your projects advantageous in terms of precision, reliability and quality of surface outcomes, aiding our success in all industrial applications. Contact us for further details.

FAQ’s

Steel shot is round, giving a smoother finish whereas steel grit is angular and more aggressive and is used to clean heavy-duty and profile surfaces.

Yes, steel shot is very much durable and can be re used several times, which makes it a cost-effective and efficient solution in abrasives.

Steel shot is extensively utilized in the automotive, aerospace, construction, metal fabrication, and heavy machine sectors to clean, surface prepare and peen.